.

How Magna’s 360° Rotating Tank Heads are Expanding Cleaning

In the pharmaceutical industry, ensuring 360° Rotating Tank Head tanks/reactors are kept in perfect condition is crucial. To meet strict quality and regulatory requirements, pharmaceutical companies are adopting new, advanced methods to improve tanks/reactors cleaning. One major innovation that’s transforming this process is the use of rotating tank cleaning heads. These devices offer more efficient and effective ways to clean tanks.

Challenges of Traditional Tank/Reactors Cleaning

Pharmaceutical companies use tanks/reactors for Batch Processing stuff like raw materials and finished products. But the Traditional method of cleaning these tanks/reactors aren’t great. They’re slow, not very good at getting all the dirt out, and they waste water and cleaning chemicals. This can lead to problems like mixing up different medicines and wasting time.

The Innovation: Magna 360° Rotating Tank Cleaning Heads

Now, here’s where the exciting part comes in. The Magna 360° Rotating Tank Cleaning Heads are like magic wands for tank/reactor cleaning.

super benefits

- Cleaning Super Speed

- Saving Water and Chemicals

- Keeping Things Super Clean

- Perfect for Any Tank

- Less Downtime

How 360° Rotating Tank Cleaning Head

Used in Pharma..?

Rotating tank/reactor cleaning heads find a multitude of applications in various areas of pharmaceutical manufacturing

- Raw Material Tanks/Reactors

- Batch Processing Tanks/Reactors

- Fermentation Tanks/Reactors

- Finished Product Storage

In Conclusion

The pharmaceutical world is getting a big upgrade by using 360° Rotating Tank Cleaning Heads. They make tanks/reactors cleaning faster, greener, and follow all the rules. By using this new technology, pharmaceutical companies are not only making better medicines but also saving time, which is a big deal in this industry.

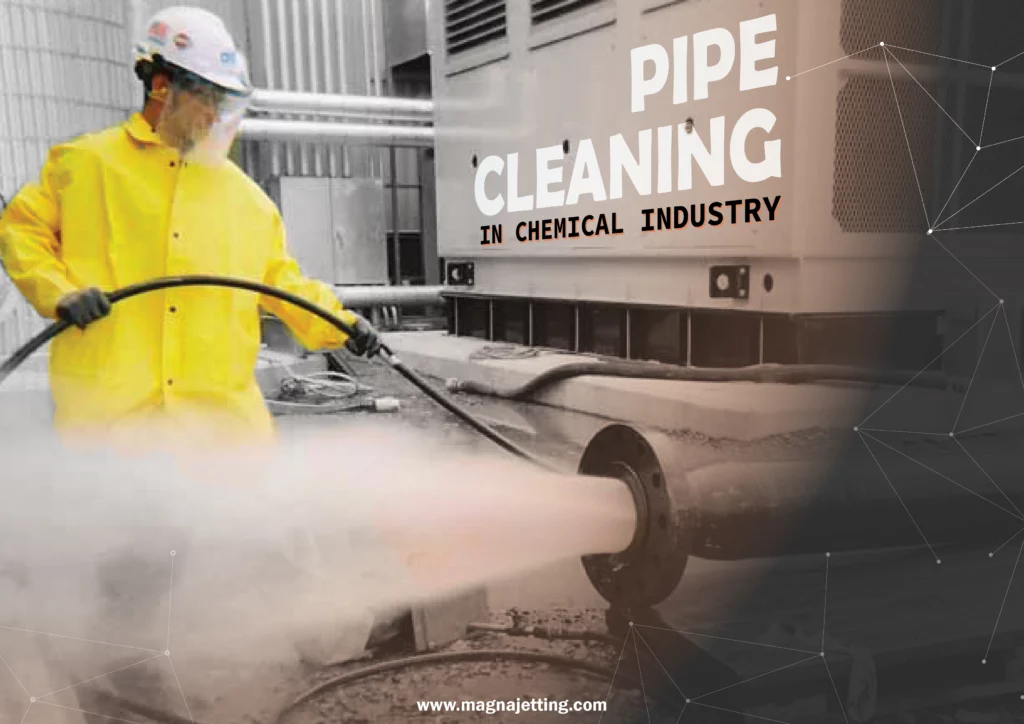

Chemical Pipeline Maintenance with High-Pressure Washer

high-pressure washer Ensuring chemical pipelines stay clean is super important to avoid problems like blockages, rust, and other gunk that can mess with safety and productivity. A great way to keep things in check is by using a high-pressure washer.

Why are clean pipelines such a big deal?

Chemical stuff moving through pipes can leave behind yucky stuff that slows things down and makes pipes weak. Regular cleaning of pipes ensures that everything runs smoothly.

The innovation of high-pressure water jets

These jets use super-strong water power, like 5,000 to 40,000 PSI. They have special nozzles that blast away deposits, making sure the pipes stay strong by getting rid of scale, rust, and other junk.

Why high-pressure washer cleaning?

a. Keeps pipes strong: It doesn’t damage the pipes, making them last longer.

b. Works on different pipes: good for steel and concrete pipes.

Safety first

Using high-pressure water jets keeps people safe by reducing accidents and limiting exposure to dangerous stuff.

we understand the paramount importance of safety in industrial environments. Our high-pressure water jetting systems play a crucial role in ensuring the well-being of workers by minimizing the risks associated with traditional cleaning methods. Using high-pressure water jets keeps people safe by reducing accidents and limiting exposure to dangerous substances.

Success stories

Check out stories where this cleaning method improved how fast things flow in pipes, reduced downtime, and made everything safer.

Future trends

Get ready for advanced stuff like robots, smart tech, and remote control to help keep pipes in top shape.

In conclusion

Efficient pipeline maintenance is crucial for sustained productivity and safety. High-pressure washer cleaning, surpassing traditional methods, emerges as a reliable solution. Embracing innovative technologies ensures a sustainable cleaning solution for chemical pipelines.

In the chemical industry, maintaining pipeline integrity is crucial to prevent scale, corrosion, and debris buildup, ensuring safety and productivity. High-pressure water jet cleaning is an effective solution for this purpose.